Advanced Techniques in On-site Machining: A Comprehensive Look

The world of on-site machining has seen remarkable advancements and applications that save both time and cost. This article delves into key aspects such as Line Boring, bore repair, bore welding, and several other sophisticated techniques.

Line Boring: Precision and Efficiency

Line Boring is a crucial process used to align and bore large pieces of machinery. This technique offers an efficient and precise method for repairing worn out or poorly aligned machinery components.

- Restores functionality to large machinery

- Improves efficiency by ensuring correct alignment

- Cost-effective compared to complete part replacement

Comprehensive Bore Repair Solutions

Implementing bore repair techniques is vital for the longevity and performance of various industrial equipment. On-site bore repair services include the restoration of the circularity and alignment of bores, which is essential for the machinery’s performance.

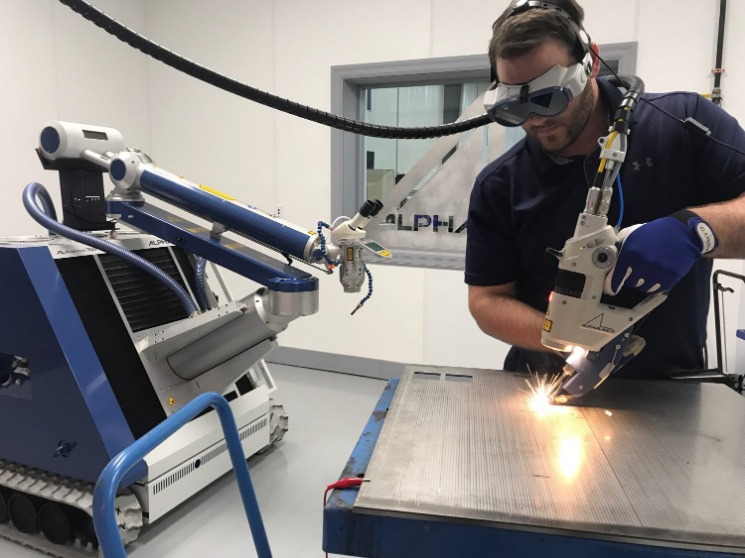

Bore Welding: Reinventing Durability

Bore welding is an innovative method that adds material to worn out or damaged bores, followed by machining to bring them back to their original dimensions. This is particularly useful for extending the lifespan of expensive components.

Slew Milling and XY Milling: Precision At Its Best

Slew milling and XY milling offer unmatched precision for a wide range of industrial applications. These milling techniques are instrumental in creating complex geometries and maintaining high levels of accuracy.

- Slew milling: Ideal for circular paths and arcs

- XY milling: Suitable for precise linear paths

Read more about bore repair here.

Bearing and Bush Installations

After performing bore repair and bore welding, installing bushings and bearings ensures the restoration of machinery’s internal geometry. Accurately installed bushings and bearings can significantly enhance the mechanical reliability and performance.

Face Welding: Restoring Flat Surfaces

Face welding is used to repair and restore flat surfaces that have worn down over time. This technique is crucial for components like flanges and large flat surfaces used in various industrial machines.

FAQs

-

What is Line Boring?

Line Boring is a machining process used to enlarge, align, and finish out-of-alignment or worn bearing bores.

-

How does Bore Welding help in bore repair?

Bore welding adds material to worn-out bores, allowing them to be machined back to their original dimensions, thereby extending the life of the component.

-

What is the difference between Slew Milling and XY Milling?

Slew milling is used for creating circular paths and arcs, whereas XY milling is ideal for achieving precise linear paths.

Leave a Reply