Efficient Restoration Techniques in Heavy Machinery: A Comprehensive Guide

Maintaining and repairing heavy machinery is crucial for ensuring operational efficiency and longevity. In this guide, we explore various advanced *on-site machining* methods such as Line Boring, *bore repair*, and bore welding, and their applications.

Understanding Line Boring

Line Boring is a precision machining process used to restore the alignment and integrity of bores in major equipment structures like the chassis or frames. Misalignments can be corrected, and bore diameters can be restored to their original specifications.

Applications of Line Boring

- Excavator arms

- Construction equipment hinges

- Industrial machinery pivot points

On-Site Machining

On-site machining eliminates the need to dismantle large and heavy components and transport them to a workshop, resulting in significant time and cost savings.

On-Site Machining Techniques

- Slew Milling: Used for the repair of large rotating elements

- XY Milling: Precise horizontal and vertical milling

Bore Repair and Bore Welding

Over time, the bores in heavy machinery can wear out. Bore repair and *bore welding* are effective solutions to restore these critical elements.

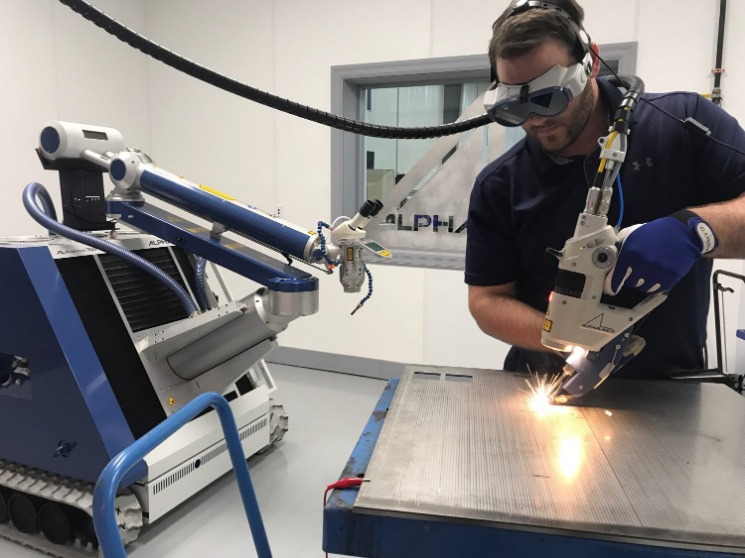

Bore Welding Process

- Initial assessment and preparation of the bore surface

- Application of weld material to rebuild the bore

- Final machining to restore the bore to the specified dimensions

Specialized Welding Techniques

Beyond bore welding, other specialized welding methods include *bush install* and face welding. These techniques ensure the precise fitting and alignment of critical components.

Bush Install

The *bush install* process involves inserting a bushing into a worn-out bore to restore optimal fit and function.

Face Welding

*Face welding* is used to rebuild worn or damaged surfaces, ensuring the full restoration of machinery components.

Read more about Line Boring here.

FAQs

- What is Line Boring used for?

Line Boring is used to accurately repair and realign worn or misaligned bores in heavy machinery. - Why is on-site machining beneficial?

On-site machining reduces downtime and eliminates the costs associated with transporting heavy machinery to and from repair facilities. - What materials can be welded using bore welding?

Bore welding can be performed on a variety of materials including steel, aluminum, and other alloys.

Leave a Reply